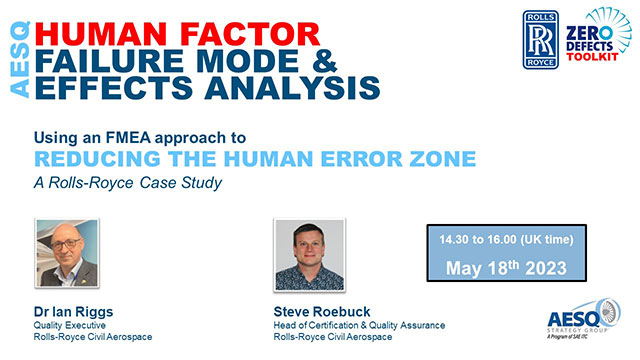

- Webinar Series: “AESQ Process Failure Mode & Effects Analysis (PFMEA) – AS13100 Process FMEA Requirements - September 2021” presented by Dr. Ian Riggs, Rolls-Royce

Led by Dr Ian Riggs, this series of interactive webinars describes the intent of the AESQ AS13100 requirements for Process FMEA and Control Plans and how they link to the effective deployment of Advanced Product Quality Planning (APQP) and a Zero Defect Strategy.

These webinars explain how AS13100 Process FMEA and Control Plans can be developed, maintained and improved using real examples of best practice from across the industry. They illustrate the unique approach to the use of Reference Process FMEAs to help standardize the organization’s PFMEAs and to reduce the length of time taken to create them.

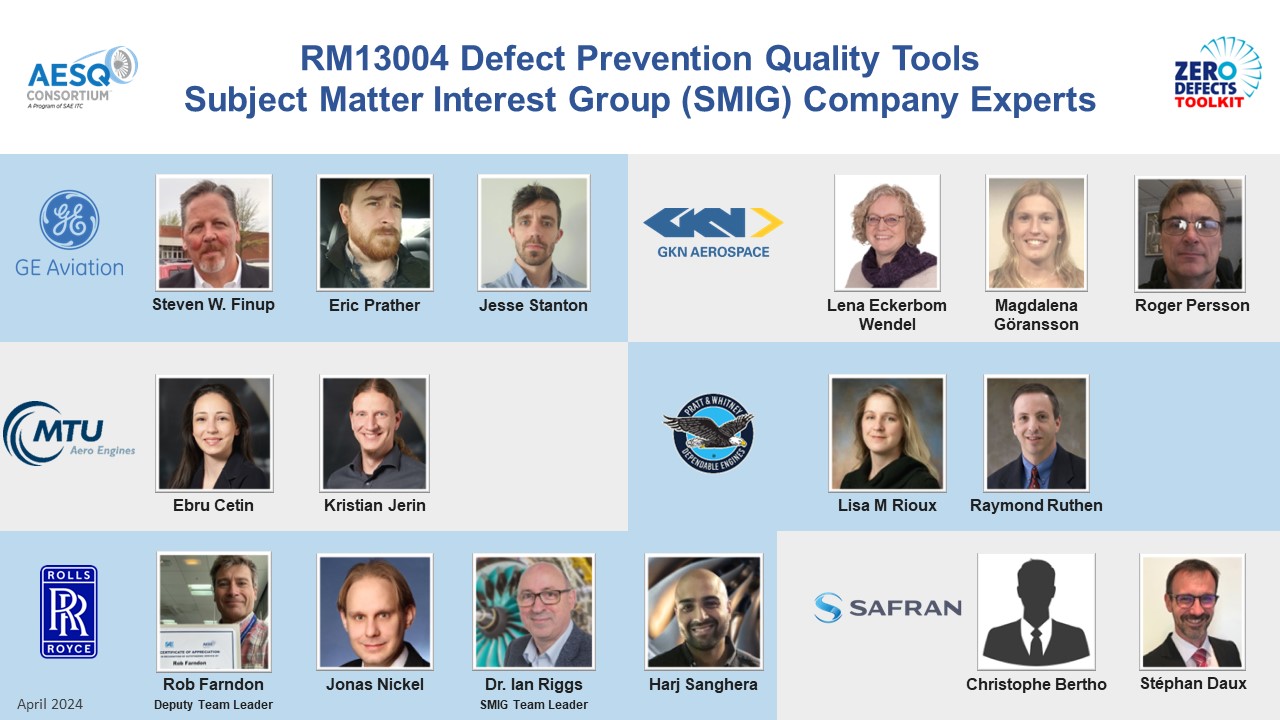

Subject Matter Interest Group Team Leader

Subject Matter Interest Group Team Leader

Dr. Ian Riggs

Quality & HSE Executive

Rolls-Royce

Subject Matter Interest Group Team Leader

Subject Matter Interest Group Team Leader